E-mail: info@solidecking.com

tel-phone:86-21-63803633

Address:Room 103, Jinfeng Building, No. 31 Hengfeng Road, Jing'an District, Shanghai

Mobile phone:13816755915 ©2016 Leshang Technologies Co., Ltd.

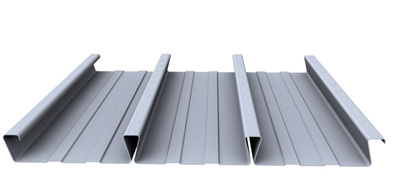

SD53-600 Installation instructions

Laying

SD53 floor deck shall be laid with the sheeting ribs aligned in the direction of the designed spans. Other details include the following:

· The slab supports shall be prepared for bearing the slip joints as required.

· Lay SD53 sheets continuously over each slab span without any intermediate splicing or jointing.

· Lay SD53 sheets end to end. Centralise the joint at the slab supports. Where jointing material is required the sheets maybe butted against the jointing material.

· Support SD53 sheets across their full width at the slap support lines and at the propping support lines.

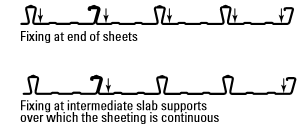

· For the supports to carry the wet concrete and construction loads, the minimum bearing is 50mm for ends of SD53 sheets, and 100mm for intermediate supports over which the sheeting is continuous.

· In exposed applications, treat the end and edges of the SD53 sheets with a suitable edge treat the end and edges of the SD53 sheets with a suitable edge treatment to prevent entry of moisture.

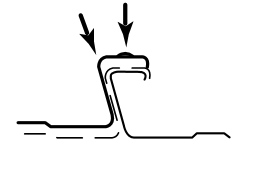

Interlocking of sheets

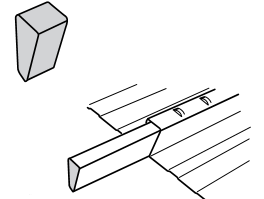

· Overlapping ribs of SD53 sheeting are interlocked. Either of two methods can be used in most situations, though variations may also work.

· In the first method, lay adjacent sheets loosely in place. Place the female lap rib overlapping the male lap rib of the previous sheet and apply foot pressure, or a light kick, to the female lap rib.

Method 1

· In the second method, offer a new sheet at an angle to one previously laid, and then simply lower it down, through an arc.

Method2

Method2

If sheets don’t interlock neatly (perhaps due to some damage or distortion from site handling or construction practices) use screws to pull the laps together tightly (Fastening side-lap joints).

Installing SD53 sheets on steel frames

General fastening of SD53 sheet

Sheet units shall be anchored to steel supporting members including perimeter support steel and/or bearing walls by arc spot puddle welds of the following diameter and spacing, fillet welds of equal strength, or mechanical fasteners.

· A minimum visible 12mm diameter arc puddle weld shall be used. Weld metal shall penetrate all layers of sheets material, and shall have good fusion to the supporting members.

· Edge ribs of sheets shall be welded at each support. Space additional welds an average of 200 mm apart but not more than 300 mm.

· When used, fillet welds shall be at least 30mm long.

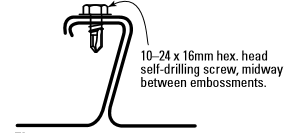

· Mechanical fasteners, either powder actuated, pneumatically driven, or screws, shall be permitted in lieu of welding to fasten sheets to supporting framing.

· Drive nails should be powder-activated, steel nails 4mm nominal diameter, suitable for structural steel of 4mm thickness or greater.

· For structural steel up to 12mm thick, use 12-24 x 38mm self –drilling self-tapping hexagon head screws.

· For structural steel over 12mm thick, pre-drill and use 12-24 x 16mm hexagon head screws.

Fastening composite beams

In Projects of composite beam construction the SD53 sheeting shall be fastened. This provision requires a fixing in each pan at each composite beam.

Stud welding through the sheet has been considered a suitable securing method for the sheeting in a composite beam; however some preliminary fixing by one of the methods mentioned above is necessary to secure the sheeting prior to the stud welding. Some relevant welding requirements are:

· Mating surfaces of steel beam and sheeting to be cleaned of scale, rust, moisture, paint, overspray, primer, sand, mud or other contamination that would prevent direct contact between the parent material and the SD53;

· Welding shall be done in dry conditions by a certified welder;

· For pre-painted SD53 sheets, special welding procedures may be necessary;

· For sheets transverse to beams, stud welding shall be tween pan flutes to ensure there is no gap between mating surfaces.

·

Fastening side-lap joints

If SD53floor deckhas been distorted in transport, storage or erection, side-lap joints may need fastening to maintain a stable platform during construction, to minimize concrete seepage during pouring, and to gain a good visual quality for exposed soffits.

Fixing at a side lap

Fitting pour stop

Pour stop is a simple L-shaped section that simplified the installation of most SD53 slabs. It is easily fastened to the SD53 sheeting, neatly retaining the concrete and providing a smooth top edge for quick and accurate screeding. We make it to suit any slab thickness.

Pour stop is easily spliced and bent to form internal and external corners of any angle and shall be fitted and fully fastened as the sheets are installed. There are various methods of forming corners and splices.

Fasten Pour stop to the underside of unsupported SD53 panels every 300mm. The top flange of Pour stop shall be tied to the ribs every 600mm (or less if aesthetics are required) with straps formed on –site using builder’s strapping 25mm x 1.0mm. Use 10-16 x 16mm self –drilling screws.

Make sure that the zinc coating on Pour stop matches the corrosion protection requirements of your job.

Holes in sheeting

SD53 sheets acts as longitudinal tensile reinforcement similarly to conventional bar or fabric reinforcement does in concrete slabs. Consequently, holes in SD53 sheets, to accommodate pipes and ducts, reduce the effective area of the steel sheeting and can adversely effect the performance of a slab. Some guidelines for holes are:

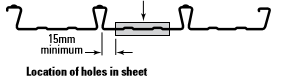

· Place holes in the central pan of any sheet, with a minimum edge distance of15mm from the rib gap.

· Holes should be round, with a maximum diameter of 150mm.

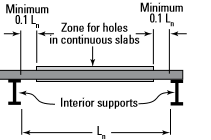

· For slabs designed as a continuous slab: space holes from an interior support of the slab no less than one tenth of a clear span.

Note: In the event of SD53 ribs being cut for larger penetrations, sufficient reinforcing steel and detailing is required to replace lost SD53 ribs. Attention to propping at these locations is essential.

Sealing

Seepage of water or fine concrete slurry can be minimised by following common construction practices. Generally gaps are sealed with End closure between the abutting ends of SD53 sheet. If there is a sizeable gap you may have to support the waterproof tape.

E-mail: info@solidecking.com

tel-phone:86-21-63803633

Address:Room 103, Jinfeng Building, No. 31 Hengfeng Road, Jing'an District, Shanghai

Mobile phone:13816755915 ©2016 Leshang Technologies Co., Ltd.